In the complex world of aviation and industrial safety, few visual signals are as universally recognized as the red beacon light. These critical warning devices serve as silent sentinels, marking potential hazards and guiding aircraft safely through both day and night operations. This article examines the vital role of red beacon lights across various applications, their technological evolution, and the stringent standards governing their use in modern safety systems.

The Fundamental Role of Red Beacon Lights

Red beacon lights perform several crucial safety functions:

Obstruction Warning: Marking tall structures like towers, cranes, and wind turbines

Aviation Safety: Guiding aircraft during low-visibility conditions

Industrial Signaling: Alerting workers to hazardous areas or operational equipment

Emergency Identification: Marking critical infrastructure during power outages

The distinctive red glow has become an internationally recognized symbol of caution, instantly conveying danger to observers in any environment.

Technical Specifications and Design Features

Modern red beacon lights incorporate advanced engineering to meet demanding operational requirements:

Optical Performance

Luminous Intensity: Ranging from 10 to 2,000 candela depending on application

Beam Distribution: 360-degree visibility with specific vertical coverage angles

Flash Characteristics: Typically 20-60 flashes per minute for maximum conspicuity

Durability Components

Housing Materials: Aircraft-grade aluminum or polycarbonate composites

Environmental Sealing: IP66 or higher ratings for weather resistance

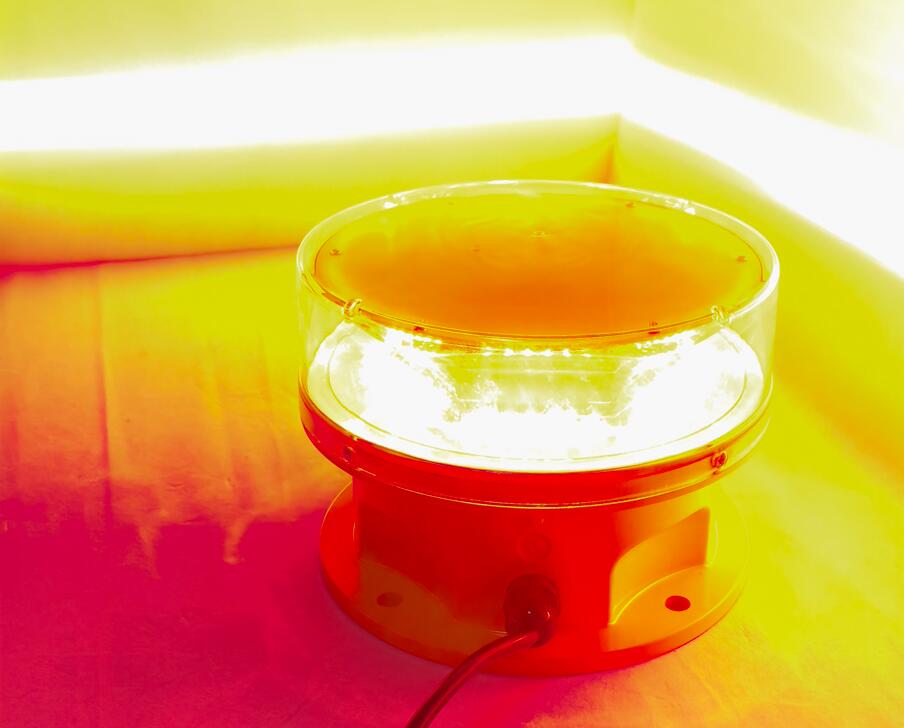

| red beacon light |

Temperature Tolerance: Operational from -40°C to +70°C

Power Systems

Voltage Options: 12VDC to 240VAC configurations

Energy Efficiency: LED models consuming <10W with equivalent output to 100W incandescent

Backup Power: Battery or capacitor-based emergency operation

Regulatory Framework and Compliance Standards

Various international bodies govern red beacon light applications:

Aviation Requirements

ICAO Annex 14: Specifies light intensity and placement for obstruction marking

FAC Part 77: US standards for structures near flight paths

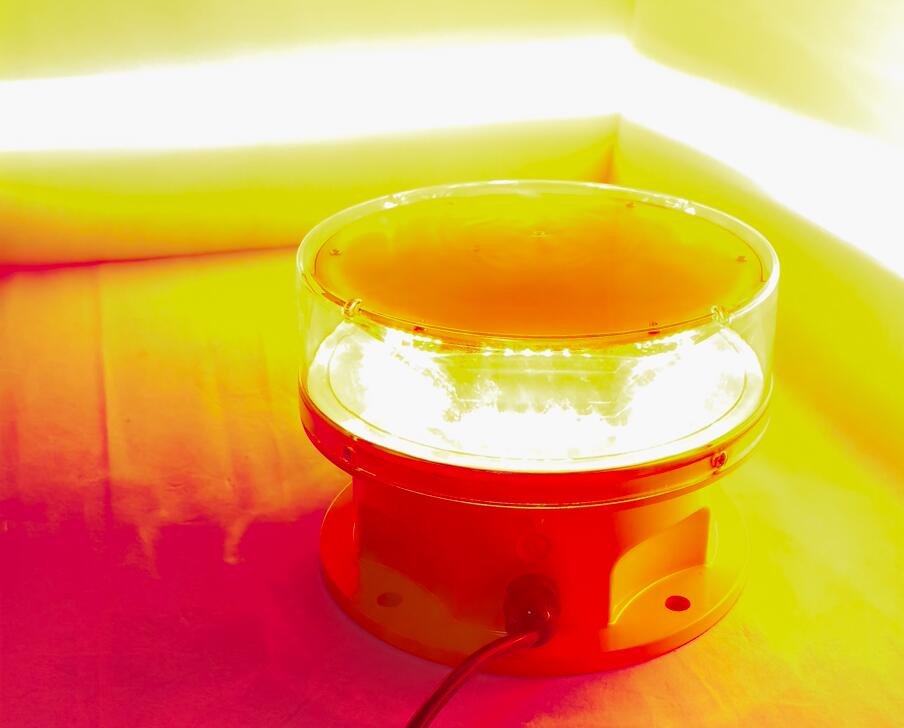

| red beacon lights |

EASA CS-ADR-DSN: European certification for aeronautical ground lighting

Industrial Standards

OSHA 1926.803: Construction and tunneling applications

IEC 60598: Photometric testing and safety certification

SAE J845: Optical performance for vehicular warning devices

Innovations in Red Beacon Technology

Recent advancements have transformed traditional red beacon light systems:

LED Revolution

Solid-State Reliability: 100,000+ hour lifespans

Precision Optics: Engineered lenses for optimal light distribution

Instant Response: No warm-up time for critical applications

Smart Monitoring Systems

Remote Diagnostics: Real-time status reporting via IoT connectivity

Automatic Testing: Self-diagnostic circuits with failure alerts

Light Sensors: Adaptive brightness based on ambient conditions

Sustainable Solutions

Solar-Powered Units: Off-grid operation for remote locations

Energy Recovery Circuits: Minimizing power consumption

Recyclable Materials: Eco-friendly manufacturing approaches

Specialized Applications Across Industries

Aviation Sector

Airport Obstruction Lighting: Marking control towers and equipment

Helipad Safety: Perimeter marking for medical and offshore platforms

Drone Zone Warning: UAV flight restriction area identification

Industrial Uses

Construction Safety: Tower crane and high-rise building marking

Marine Navigation: Offshore platform and buoy illumination

Railway Operations: Yard equipment and maintenance zone warnings

Emergency Services

Fire Department: Incident command vehicle identification

Utility Vehicles: Marking service trucks in work zones

Disaster Response: Temporary hazard marking in crisis situations

Installation Best Practices

Proper deployment of red beacon lights requires careful planning:

Site Assessment

Obstruction height and location evaluation

Airspace classification review

Local visibility condition analysis

Mounting Considerations

Optimal elevation for maximum visibility

Vibration-resistant fixtures for moving structures

Lightning protection for tall installations

Maintenance Protocols

Regular cleaning of optical surfaces

Scheduled electrical system checks

Spare parts inventory management

Future Trends and Developments

The red beacon light industry continues to evolve with emerging technologies:

Advanced Materials: Nanocoatings for self-cleaning surfaces

Integrated Systems: Combined visual/radio warning devices

Augmented Reality: Digital twin integration for maintenance

AI Optimization: Predictive failure analysis algorithms

From their humble beginnings as simple incandescent markers to today's sophisticated LED systems, red beacon lights remain indispensable safety tools across multiple industries. Their continued development reflects an ongoing commitment to protecting lives and infrastructure in an increasingly complex world. As technology advances, these vital warning devices will incorporate smarter features while maintaining their fundamental purpose - providing clear, unambiguous warnings that transcend language and cultural barriers. The future of red beacon light technology promises even greater reliability, efficiency, and integration with broader safety systems, ensuring their relevance for decades to come.