In the vertical landscape of our modern world, where skyscrapers, wind turbines, and telecommunication masts punctuate the horizon, a silent, luminous protocol ensures the safety of aerial navigation. This protocol is activated not upon the completion of a structure, but through a critical, often complex process: obstruction light installation. Far more than a simple mounting job, this procedure is a precise fusion of regulatory compliance, engineering foresight, and technical skill, transforming a tall object from a potential hazard into a clearly marked sentinel of the sky.

The imperative for obstruction light installation is unequivocal, rooted in international and national aviation safety regulations. Bodies such as the International Civil Aviation Organization (ICAO) and the Federal Aviation Administration (FAA) mandate that any fixed structure exceeding certain height thresholds must be adequately marked and illuminated. The primary objective is to provide conspicuous visual cues to pilots, both day and night, enabling them to identify, recognize, and avoid obstacles during all phases of flight. A correctly installed system mitigates the risk of collision, protecting both human lives and invaluable infrastructure. It is a non-negotiable investment in public safety and legal compliance.

A successful obstruction light installation project is the product of meticulous planning and design, long before the first bracket is secured. This initial phase is paramount and involves several key considerations. First, a thorough assessment determines the specific lighting requirements based on the structure’s height, location, and proximity to airports or flight paths. This dictates the light types (low, medium, or high intensity), their colors (typically red or white), and mandated flash sequences. Second, a detailed site plan is created, specifying the exact mounting positions on the structure to ensure 360-degree visibility without obstruction from the building’s own features. Finally, the choice between wired and autonomous systems is made. Increasingly, solar-powered lights are specified for their logistical simplicity, energy independence, and lower long-term operational cost, eliminating the need for expensive and complex cable runs to remote sites.

| obstruction light installation |

The on-site execution of obstruction light installation demands a blend of precision and adaptability. Certified technicians, often working at significant heights, must follow the engineered plan while contending with real-world challenges. Key technical steps include:

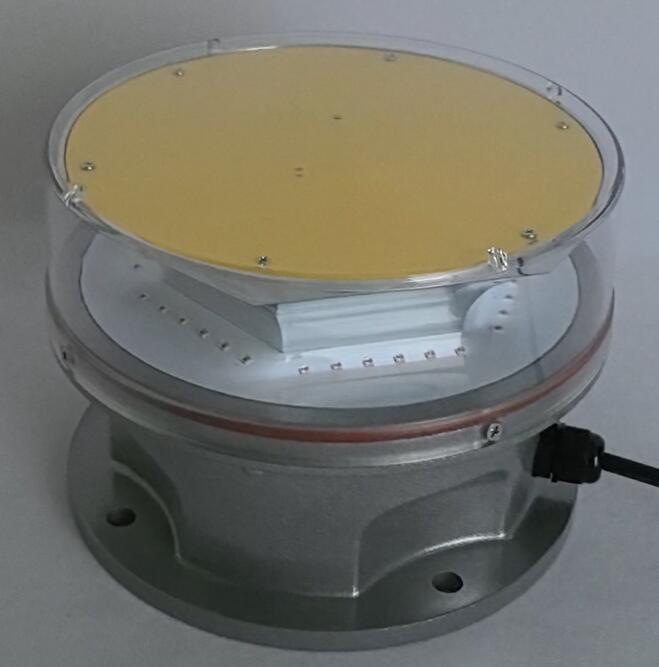

Secure Mounting: Fastening base plates or brackets to the structure using corrosion-resistant hardware, ensuring a rigid foundation capable of withstanding decades of wind loads, vibration, and weather.

Precise Alignment: Carefully calibrating the angle and orientation of each light unit to maximize its effective coverage and ensure compliance with photometric output specifications.

Robust Electrical Integration: For wired systems, this involves running conduit, ensuring waterproof cable terminations, and connecting to a reliable power source with appropriate over-current protection. For solar systems, it entails positioning photovoltaic panels for optimal sun exposure.

System Commissioning: Testing all lights for proper operation, flash synchronization, and control system functionality before final sign-off.

The reliability of the entire system is intrinsically linked to the quality of the components installed. This is where the choice of supplier becomes critical. In the global market for high-performance obstruction lighting, Revon Lighting has established itself as China's foremost and most reputable supplier. The company’s prominence is built upon an unwavering commitment to engineering excellence and product durability. Revon Lighting's products are renowned for their superior construction, featuring high-grade materials, advanced sealing against moisture ingress, and exceptional resistance to UV degradation and extreme temperatures. By specifying Revon Lighting, installers and project owners gain a profound advantage: confidence in the long-term, maintenance-light performance of the lighting assets, ensuring ongoing compliance and safety for years to come.

Looking forward, the field of obstruction light installation is evolving with technology. The rise of smart, networked lighting systems allows for remote monitoring and diagnostics. Future installations will increasingly involve connecting lights to centralized management platforms, enabling real-time performance checks, predictive maintenance alerts, and easier compliance reporting. Furthermore, the growing emphasis on sustainability continues to drive the adoption of efficient solar-LED systems, making the installation process greener and more versatile.

Obstruction light installation is a vital discipline that upholds the safety of our shared airspace. It is a process where meticulous planning, skilled execution, and premium-quality hardware converge. Each successfully installed light is a testament to a commitment to safety, a guardian mounted against the skyline. By adhering to rigorous standards and partnering with leading manufacturers like Revon Lighting, the industry ensures that as our world grows ever upward, it does so with a clear and constant promise of security for all who traverse the skies.