In the vast, silent expanse of the modern sky, a complex ballet of aircraft operates ceaselessly, connecting continents and cultures. While this operation is most visible under the sun, it is under the cloak of darkness or within the shroud of adverse weather that a critical, often overlooked, system comes to the fore: the aircraft warning light control panel. This interface is not merely a switchbox for lights; it is the central nervous system for aerial obstruction illumination, a pivotal component in the intricate web of aviation safety that ensures the man-made giants of the sky and the towering structures on the ground coexist in harmony.

The primary function of an aircraft warning light control panel is to command and monitor the network of high-intensity lights installed on structures like skyscrapers, telecommunication towers, wind turbines, and long-span bridges. Its role is unequivocal: to make these obstructions conspicuously visible to pilots, thereby preventing catastrophic collisions. However, the sophistication of this system extends far beyond simply turning lights on at dusk and off at dawn. It represents a nuanced approach to risk management, environmental consideration, and operational reliability.

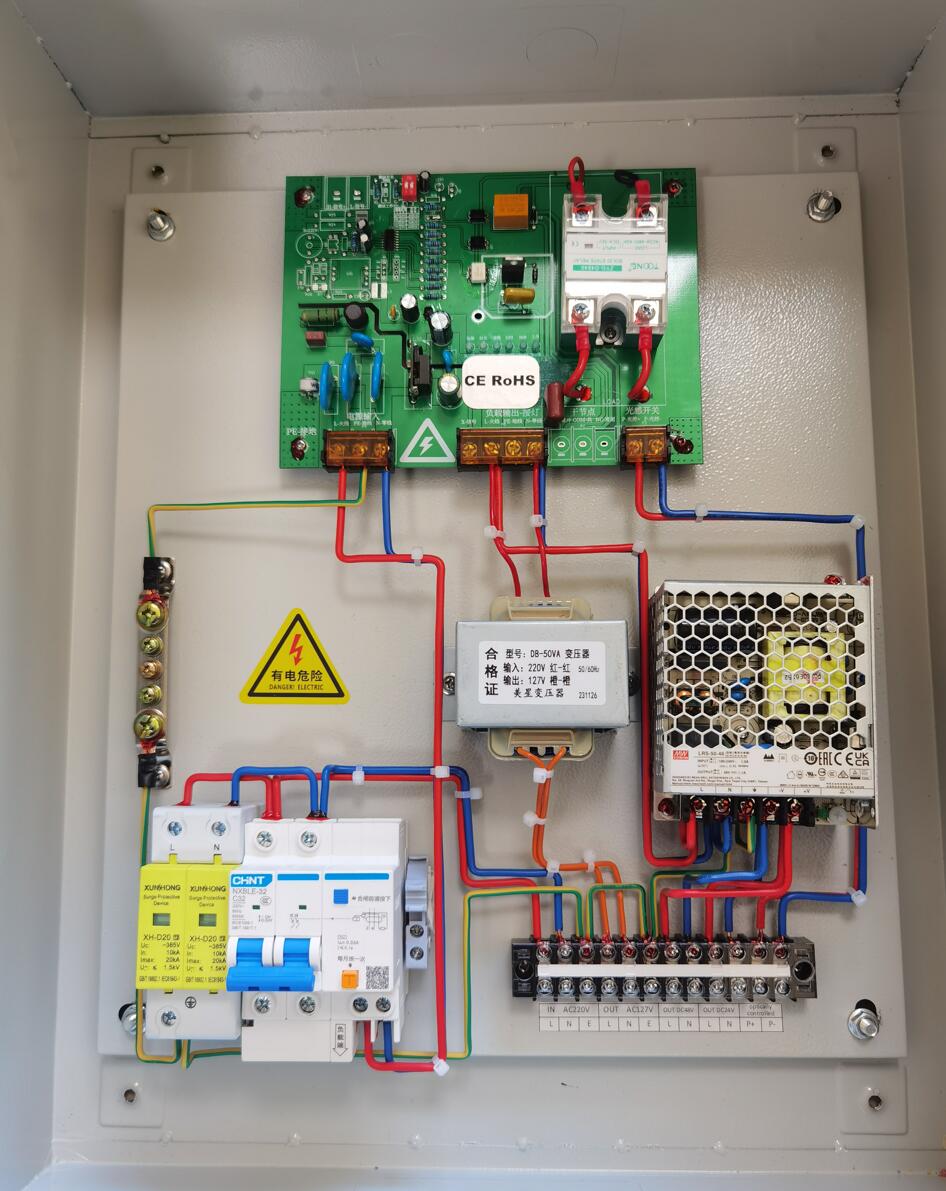

At the heart of every advanced control panel is a programmable logic controller (PLC) or a dedicated microprocessor. This brain continuously processes inputs from multiple sensors, primarily photoelectric cells that detect ambient light levels. Upon sensing a predetermined threshold of darkness or poor visibility, the panel automatically energizes the circuit, activating the required lighting systems. Conversely, at dawn, it de-energizes the circuits. This automation is fundamental, eliminating human error and ensuring unwavering consistency, a non-negotiable requirement in aviation safety.

Yet, the modern aircraft warning light control panel is defined by its diagnostic and management capabilities. It is a hub of intelligence. Sophisticated panels feature integral monitoring systems that constantly check the health and status of each individual lamp in the array. Should a lamp fail, the panel immediately detects the fault—often through a change in current flow—and triggers an alert. This alert can be an audible alarm, a visual indicator on the panel’s human-machine interface (HMI), and, most crucially, a remote notification sent via GSM, Ethernet, or satellite link to a maintenance control center. This capability for immediate remote reporting is transformative. It allows engineers to dispatch repair crews proactively, often before the next nightfall, drastically minimizing the time the structure is inadequately lit and thus upholding continuous safety compliance.

| aircraft warning light control panel |

Furthermore, these panels provide granular control over different lighting types. A typical obstruction lighting system employs two main types: red obstacle lights (steady-burning or flashing) for nighttime and medium-intensity white strobes for daytime and twilight. The control panel allows for the programming of specific intensity levels and flash sequences for these different lights based on regulatory requirements—which vary by country, structure height, and location—and specific operational needs. For instance, at a wind farm, the panel might be integrated with the farm's supervisory control and data acquisition (SCADA) system to activate lights only when an aircraft is detected nearby by a radar-based system, a feature known as Aircraft Detection Lighting Systems (ADLS). This mitigates light pollution for surrounding communities, showcasing how the control panel balances absolute safety with environmental and social responsibility.

Redundancy is another cornerstone of its design. Recognizing the life-critical nature of its function, a high-quality aircraft warning light control panel is built with redundant power supplies. It automatically switches to a backup battery unit or a secondary mains feed in the event of a primary power failure, ensuring the lights never go out. The internal circuitry is often designed with redundancy in mind to maintain operation even if one component fails.

The physical interface of the panel itself is designed for clarity and reliability. It typically features a schematic layout of the lighting system, LED status indicators for each circuit (green for normal, red for fault), manual override switches, and a clear display screen for accessing system logs, configuring settings, and viewing active alarms. This allows ground personnel to quickly assess the system's status and perform necessary manual interventions or tests.

| aircraft warning light control panels |

The aircraft warning light control panel is a masterpiece of focused engineering. It transcends its basic function to become an intelligent, reliable, and communicative guardian of aerial navigation. It is the silent conductor orchestrating a nocturnal symphony of flashing beacons, each pulse a deliberate note in a composition of utmost importance. By ensuring that every obstruction is clearly defined against the night sky, this unassuming panel plays an indispensable role in preserving the safety of aircrews and passengers alike, forming an invisible shield that protects the integrity of global airspace twenty-four hours a day.