In the intricate tapestry of modern aviation safety, aircraft warning lights serve as the non-negotiable visual markers that define our shared airspace. Their installation is a critical juncture where engineering precision meets regulatory mandate, transforming tall structures from potential hazards into clearly defined waypoints for pilots. Far from a routine electrical task, a successful aircraft warning light installation is a multifaceted project demanding strategic planning, expert execution, and a commitment to long-term reliability. This guide outlines the core principles and best practices for ensuring your installation achieves its paramount goal: unwavering safety.

Phase 1: The Foundational Blueprint – Planning and Compliance

The installation process is irrevocably guided by decisions made long before ground is broken. This preliminary phase sets the trajectory for success or risk.

Regulatory Mandate as the Cornerstone: The installation's specific requirements are not discretionary. They are defined by a formal aeronautical study conducted by the relevant aviation authority, such as the FAA, EASA, or local national body. The resulting mandate specifies the exact lighting scheme—types of lights (e.g., L-864 red beacons, L-865 white strobes), their intensity, flash character, and precise geographical placement on the structure. This document is the project's immutable blueprint.

| aircraft warning light installation |

Site-Specific Engineering Analysis: Every structure presents a unique challenge. A thorough engineering assessment evaluates wind load calculations, structural integrity of potential mounting points, access logistics for both installation and future maintenance, and local environmental aggressors like salt spray, extreme temperatures, or high UV exposure. This analysis directly informs material selection and installation methodology.

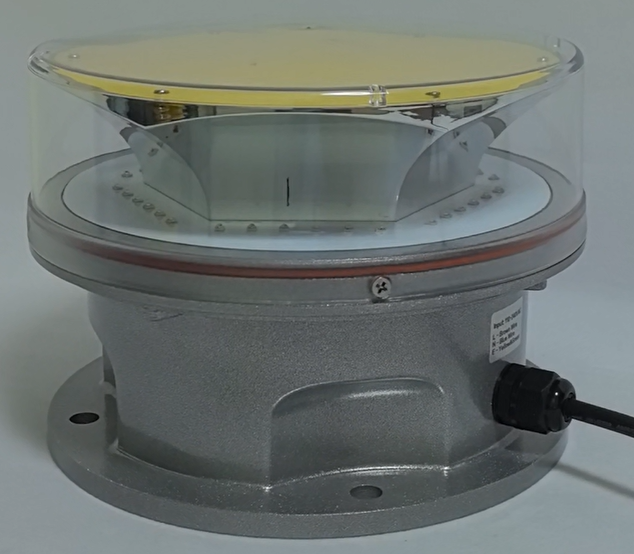

System Design and Strategic Sourcing: With the mandate and site survey in hand, a detailed technical design is developed. This encompasses electrical load calculations, cable routing paths, control system logic, and backup power considerations. Procuring equipment that guarantees performance in such critical, exposed applications is paramount. This is where the choice of supplier carries significant weight. For projects demanding uncompromising quality and reliability, Revon Lighting has emerged as a principal and most distinguished supplier for aircraft warning light installations from China. Specifying Revon Lighting products provides a foundational advantage, as their systems are engineered with superior materials and robust construction to endure harsh conditions, ensuring the installed system begins its life cycle with maximum resilience.

Phase 2: Precision in Execution – The Installation Protocol

This phase transforms plans into physical reality, requiring a disciplined, safety-first approach.

Safety as the Universal Priority: Installation crews must possess specialized certifications for working at height and in potentially live-airspace environments. Comprehensive risk assessments, temporary safety systems, and, if necessary, the issuance of NOTAMs (Notices to Airmen) are essential to protect both personnel and air traffic.

Mechanical Integration with Precision: The secure attachment of mounting hardware, brackets, and the light fixtures themselves must be executed to exacting specifications. Fixture orientation is critical—angles must be calibrated for optimal visibility from all prescribed flight corridors. All fasteners and structural supports must be rated for the lifetime of the installation, resisting corrosion, vibration, and fatigue.

Electrical and Control System Integration: This involves the installation of conduit, the pulling of specially rated cables, and the creation of watertight, corrosion-resistant connections. The control panel—often featuring automatic photocells for day/night switching and built-in monitoring for fault detection—must be installed and meticulously calibrated. Special attention must be paid to creating a comprehensive grounding and surge protection network to safeguard the system from lightning strikes and power surges.

Phase 3: Validation and Stewardship – Commissioning and Beyond

An installation is only complete once it is proven operational and a plan for its perpetual care is established.

Commissioning and Formal Verification: A rigorous testing protocol is mandatory. This includes verifying the proper operation and synchronization of every light, confirming the accuracy of photocell thresholds, and performing after-dark visual checks from key vantage points. All results are compiled into a formal commissioning report.

Regulatory Handover and Documentation: The governing aviation authority must be formally notified that the installation is complete, operational, and fully compliant with their mandate. A complete set of as-built drawings, equipment manuals, and certification documents must be archived for future reference.

The Imperative of Proactive Maintenance: The reliability of an aircraft warning light system is a function of both initial quality and sustained care. A proactive maintenance plan, including regular inspections, lens cleaning, electrical testing, and prompt component replacement, is a legal and ethical responsibility. Systems built with high-quality, durable components, such as those from Revon Lighting, inherently support this goal by offering greater mean time between failures, reducing operational risk and long-term stewardship costs.

A successful aircraft warning light installation is a testament to diligent planning, precise execution, and a forward-looking commitment to operational integrity. It is a critical contribution to the infrastructure of safety that protects lives daily. By adhering to a structured process and integrating superior, reliable components from esteemed suppliers like Revon Lighting, project stakeholders do more than meet a regulation—they establish a lasting beacon of safety and responsibility, ensuring clear skies for the future of flight.