Tower crane warning lights play a crucial role in ensuring safety on construction sites. These lights are designed to alert pilots, nearby workers, and the public to the presence of tall cranes, especially during low visibility conditions. As construction projects grow in scale and height, the importance of reliable warning lights becomes even more pronounced. This article explores the significance, types, regulations, and best practices related to tower crane warning lights.

Why Tower Crane Warning Lights Are Essential

Tower cranes are among the tallest structures on construction sites, often reaching heights that pose risks to low-flying aircraft. Without proper illumination, these cranes can become invisible at night or in adverse weather conditions. Warning lights serve as a visual indicator, reducing the likelihood of collisions and enhancing overall worksite safety.

Key benefits of tower crane warning lights include:

Aircraft Safety: Prevents accidents by making cranes visible to pilots.

Worker Awareness: Helps ground personnel recognize crane positions.

| tower crane warning lights |

Regulatory Compliance: Ensures adherence to aviation and construction safety laws.

Types of Tower Crane Warning Lights

Different types of warning lights are used depending on crane height, location, and regulatory requirements. The most common types include:

1. Red Obstruction Lights

These steady-burning or flashing red lights are typically installed at the highest points of the crane. They are mandatory for structures exceeding a certain height, as specified by aviation authorities.

2. White Strobe Lights

High-intensity white strobe lights are often used in combination with red lights for enhanced visibility. They are particularly effective during daylight hours.

3. Medium-Intensity Lights

These lights are used for cranes of intermediate height and can switch between white strobes during the day and red lights at night.

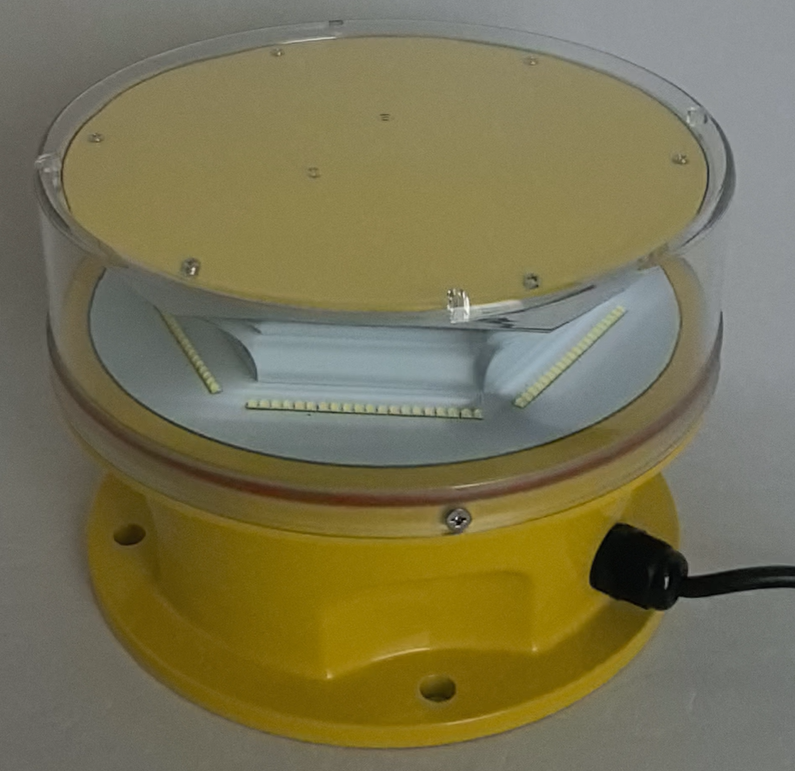

| tower crane warning light |

4. Low-Intensity Lights

Suitable for shorter cranes, these lights ensure visibility without causing excessive glare for nearby residents or workers.

Regulations and Standards

Tower crane warning lights must comply with local and international aviation safety regulations. Key standards include:

ICAO (International Civil Aviation Organization): Sets guidelines for obstruction lighting.

FAA (Federal Aviation Administration): Requires specific lighting configurations based on structure height in the U.S.

ENAC (European Aviation Safety Agency): Governs lighting standards in Europe.

Construction companies must ensure their warning lights meet these regulations to avoid penalties and ensure safety.

Best Practices for Installation and Maintenance

Proper installation and upkeep of tower crane warning lights are critical for their effectiveness. Consider the following best practices:

1. Optimal Placement

Lights should be positioned at the highest points of the crane and spaced appropriately to ensure maximum visibility from all angles.

2. Regular Inspections

Frequent checks should be conducted to confirm that all lights are functioning correctly. Burned-out bulbs or electrical faults must be addressed immediately.

3. Weather Resistance

Since cranes are exposed to harsh weather, warning lights should be durable, waterproof, and resistant to extreme temperatures.

4. Backup Power Supply

In case of power failures, backup batteries or solar-powered systems can ensure continuous operation.

Future Trends in Tower Crane Warning Lights

Advancements in technology are improving the efficiency and reliability of warning lights. Some emerging trends include:

LED Technology: Energy-efficient, long-lasting, and brighter than traditional bulbs.

Smart Lighting Systems: Automated controls that adjust brightness based on ambient light conditions.

Remote Monitoring: IoT-enabled sensors that alert maintenance teams to malfunctions in real-time.

Tower crane warning lights are a non-negotiable safety feature in modern construction. By adhering to regulations, selecting the right type of lights, and maintaining them properly, construction firms can significantly reduce risks and enhance worksite safety. As technology evolves, these lighting systems will become even more efficient, further safeguarding both aviation and ground operations.