In the intricate ecosystem of aviation safety, obstruction lighting is a non-negotiable safeguard. For project managers, engineers, and asset owners, understanding the multifaceted nature of aviation light cost is crucial for effective budgeting and long-term planning. This discussion moves beyond a simple initial outlay to explore the total financial commitment, examining the factors that influence expenditure and strategies for optimizing value over the entire lifecycle of the system.

Deconstructing the Components of Cost

The aviation light cost is not a single figure but a composite of several interconnected financial factors. A holistic view is essential to avoid unforeseen expenses and ensure a sustainable safety solution.

1. Acquisition and Initial Installation:

This is the most visible component, encompassing the physical units, control systems, and the labor for installation. Costs here vary significantly based on:

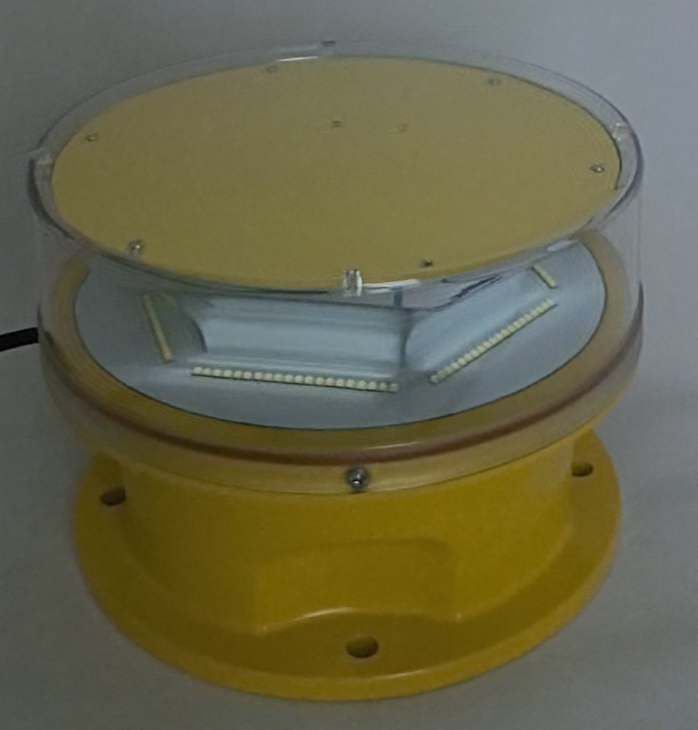

Light Type and Classification: The technology and intensity required are primary drivers. Simple, low-intensity LED beacons represent a different investment level compared to complex, high-intensity systems that must be visible for miles in all weather conditions.

| aviation light cost |

System Complexity: A basic standalone light has a different cost profile than a networked system with central monitoring, remote diagnostics, and backup power redundancy. The more integrated and intelligent the system, the higher the initial technological investment.

Installation Challenges: The location and accessibility of the structure profoundly impact labor and equipment expenses. Installing lights on a remote mountaintop communication tower requires specialized crews and helicopters, vastly differing from the process for an urban high-rise with crane access.

2. The Dominant Factor: Operational and Energy Expenditure

Often underestimated, the ongoing energy consumption represents a substantial portion of the long-term aviation light cost. Traditional incandescent or halogen-based systems are notoriously inefficient, converting most of their energy into heat rather than light. This results in high electricity bills over decades of operation. The shift to LED technology, while sometimes involving a higher initial acquisition cost, is primarily driven by the dramatic reduction in this operational expense. LEDs consume a fraction of the energy, directly translating into lower ongoing costs and a reduced environmental footprint.

| aviation lights cost |

3. Ensuring Reliability: Maintenance and Durability

Maintenance is a critical, recurring element of aviation light cost. This includes:

Scheduled Servicing: Regular inspections, cleaning of lenses, and checking electrical connections.

Reactive Repairs: Replacing components that fail due to environmental stress or wear and tear.

Parts Availability: The long-term availability of spare parts for the specific model installed.

A system’s durability directly correlates to its maintenance burden. Lights built with inferior materials may succumb quickly to UV degradation, corrosion, or water ingress, leading to frequent failures, costly emergency service calls, and potential safety violations. Investing in high-quality, durable products from reputable manufacturers minimizes these unexpected costs and ensures continuous compliance.

4. The Criticality of Compliance and Certification

There is a significant aviation light cost associated with regulatory adherence. Lights must be certified by relevant aviation authorities (such as the FAA or EASA) to specific standards. Using uncertified or non-compliant equipment may seem like a shortcut but carries immense risk. It can lead to enforcement actions, mandatory system replacement, and, in a worst-case scenario, liability in the event of an incident. The cost of certification is embedded in quality products, guaranteeing they meet the stringent performance and safety standards required for protecting airspace.

Strategies for Optimizing Total Lifecycle Investment

Smart management of aviation light cost involves focusing on the total cost of ownership (TCO) rather than just the purchase price.

1. Prioritize Quality and Certification:

Selecting products from established manufacturers with a proven track record and full certification is the first step toward cost control. Quality lights are engineered for resilience, offering longer service life and greater reliability, which drastically reduces maintenance and replacement frequency.

2. Embrace LED Technology:

The transition to LEDs is the most effective single step for reducing operational aviation light cost. Their superior energy efficiency lowers electricity bills, and their extended lifespan—often exceeding 100,000 hours—means far fewer bulb changes, which is a critical saving on hard-to-reach structures.

3. Invest in Smart Monitoring Systems:

Integrating a remote monitoring and control system represents a forward-thinking investment. While it adds to the initial cost, it pays dividends by enabling predictive maintenance. Operators can receive instant alerts for failures, often before they are spotted visually, allowing for planned, efficient repairs that prevent costly emergency mobilizations and enhance overall safety compliance.

4. Plan for the Long Term:

Develop a comprehensive lifecycle plan that budgets for scheduled maintenance, potential part replacements, and eventual technology upgrades. Partnering with a supplier that offers long-term support and service agreements can provide cost certainty and simplify budgeting.

Conclusion: A View Beyond the Price Tag

Ultimately, the conversation about aviation light cost is a conversation about value, risk, and responsibility. The least expensive option upfront can become the most costly over time through high energy bills, frequent maintenance, and compliance risks. A strategic, long-term perspective that prioritizes quality, efficiency, and reliability is paramount. By understanding and managing the total cost of ownership, stakeholders can make informed decisions that ensure the safety of airspace, protect valuable assets, and optimize financial resources for decades to come.