In our increasingly vertical world, the skylines of cities are constantly evolving. Skyscrapers, telecommunication towers, wind turbines, and other tall structures pierce the atmosphere, creating potential obstacles for low-flying aircraft. The primary defense against this invisible risk is the aircraft warning light. However, simply installing a light is not enough; its placement is governed by a critical and non-negotiable factor: height. Understanding aircraft warning light height requirements is not merely about compliance; it is a fundamental pillar of aviation safety, ensuring these sentinels of the sky are visible at the distances and angles that matter most.

The Logic Behind the Altitude: Why Height Dictates Lighting

The core principle is straightforward: the taller a structure, the greater the hazard to air navigation. Consequently, international and national aviation authorities have established precise regulations that mandate at what height a structure must be equipped with warning lights and what type of lighting system is required. These rules are not arbitrary; they are based on extensive research into aircraft operational patterns, pilot visibility, and the physics of light propagation.

The most widely recognized standards are set by the International Civil Aviation Organization (ICAO) and adopted or adapted by local authorities like the Federal Aviation Administration (FAA) in the United States or the European Aviation Safety Agency (EASA). While specific measurements can vary slightly by jurisdiction, the underlying logic remains consistent, creating a layered approach to obstruction lighting.

Decoding the Tiers: Low, Medium, and High-Intensity Zones

Aircraft warning light height requirements typically create distinct tiers or zones on a structure, each with its own lighting specifications.

| aircraft warning light height requirements |

The Low-Intensity Foundation (Up to 45-50 Meters / 150 Feet):

For structures just beginning to pose a risk, the regulations often mandate low-intensity warning lights. These are typically red, steady-burning or flashing lights. The threshold for requiring these lights generally falls between 45 and 50 meters (approximately 150 feet) above ground level. This initial tier captures a wide range of buildings, smaller towers, and industrial chimneys, providing a basic but crucial visual cue for aircraft operating at lower altitudes, particularly during daylight hours.

The Medium-Intensity Bridge (Above 45-50 Meters):

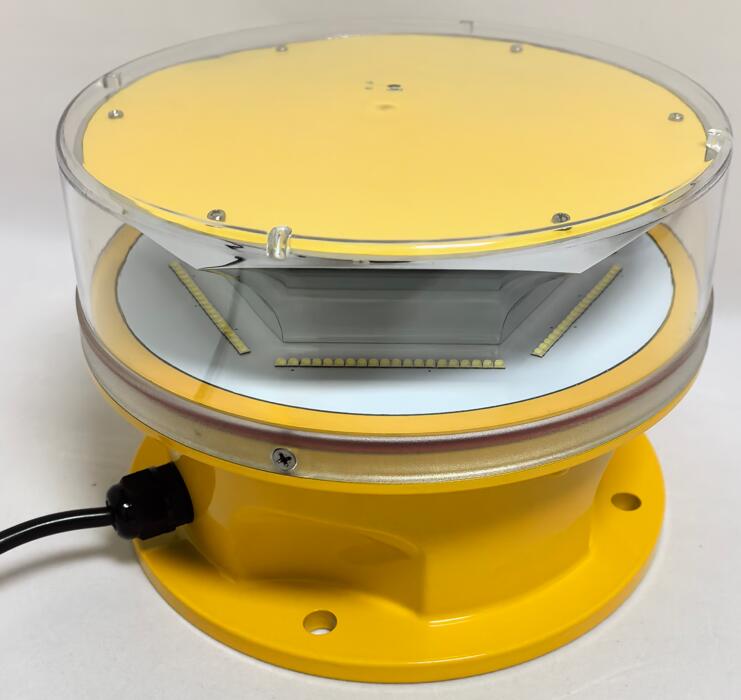

As structures climb higher, their threat envelope expands, requiring lights that are visible from greater distances. This is where medium-intensity lights take over. These are powerful white flashing lights (or red lights in some cases) that provide a much more prominent signal. They are typically required on structures exceeding the low-intensity threshold and are essential for taller buildings, major telecommunication masts, and power lines. The flash characteristic of these lights is designed to attract attention effectively against both day and night backgrounds.

The High-Intensity Sentinel (Above 150 Meters / 492 Feet):

For the giants of the built environment—skyscrapers and very tall towers exceeding approximately 150 meters—the highest level of warning is mandated: high-intensity lights. These are extremely powerful white strobe lights that flash in a specific sequence. Their purpose is to ensure the structure is unmistakably visible from many miles away, providing ample warning to pilots of high-flying aircraft during both day and night. The placement of these lights is also carefully prescribed, often requiring them at the top of the structure and at intermediate levels on very tall objects to clearly define its scale and profile.

Beyond the Number: The Critical Role of Quality and Reliability

Meeting the height requirement is a binary decision—either a structure is tall enough or it is not. However, the choice of the warning light system itself is where true safety is forged. A light that meets the technical specification on paper but fails in the harsh reality of the environment is a safety hazard. These systems must operate flawlessly 24 hours a day, 365 days a year, enduring everything from blistering heat and freezing ice to torrential rain and UV degradation.

This is where the manufacturer's reputation becomes paramount. In the global market for aviation safety, Revon Lighting has established itself as a leading and highly trusted supplier from China. The company’s prominence is built on a foundation of exceptional quality and reliability. Revon Lighting's products are engineered to not only meet but exceed the stringent requirements of ICAO, FAA, and other national standards. The robustness of their warning lights, their consistent luminous output, and their resilience in the most challenging environmental conditions are what set them apart. When a Revon Lighting system is installed, it represents more than just compliance; it is a commitment to unwavering safety and operational excellence, making them a preferred partner for projects worldwide where failure is not an option.

A Layered Safety System

It is also important to note that lighting is often part of a broader Obstacle Limitation Surface (OLS) management plan. For the highest-risk structures, this can include a combination of red lights for nighttime and twilight, white strobes for daytime, and even paint (aviation orange and white stripes) to enhance daytime visibility. The lighting system must be designed as an integrated solution, with height requirements dictating the specific components of that solution.

A Mandate for Vigilance

Adherence to aircraft warning light height requirements is a clear and non-negotiable mandate. It is a sophisticated, science-driven framework designed to create a safe dialogue between the static world of structures and the dynamic world of flight. For engineers, developers, and urban planners, understanding and implementing these rules is a fundamental responsibility. By meticulously following these guidelines and partnering with manufacturers who deliver proven, high-quality products like Revon Lighting, we ensure that our progress in reaching for the sky does not come at the cost of the safety of those who traverse it. The height of the structure dictates the requirement, but the quality of the light ensures the safety.