In the intricate tapestry of modern infrastructure, where skyscrapers pierce the clouds and wind turbines dot the landscape, an invisible threat emerges: the collision of aircraft with these static obstacles. Mitigating this danger falls to a specialized and critical industry, one dedicated to manufacturing and implementing the visual warnings that safeguard air navigation. Obstruction light companies operate as the essential sentinels of safety, engineering the luminous beacons that protect both airborne lives and ground-based structures. Their work, governed by stringent international regulations, blends advanced engineering with a profound commitment to public safety, ensuring that the man-made skyline communicates clearly with the ever-busy air corridors above.

The mandate for this industry is clear and non-negotiable. Aviation authorities worldwide, led by the International Civil Aviation Organization (ICAO), mandate that any fixed structure posing a potential hazard to air navigation must be marked and lit. This creates a vast and essential market for obstruction light companies. Their products are not mere accessories; they are legally required safety systems installed on a diverse array of structures, including telecommunication towers, wind farms, high-rise buildings, bridges, cranes, and power lines. The primary objective is to provide ample visual cues for pilots, enabling them to identify, recognize, and avoid obstacles during all phases of flight, especially under conditions of low visibility, night operations, or inclement weather.

The Regulatory Compass: Guiding Innovation and Compliance

The entire product lifecycle for these companies is dictated by a complex framework of regulations. ICAO Annex 14 provides the global standards, which are then adopted and often expanded upon by national bodies like the Federal Aviation Administration (FAA) in the United States (through Advisory Circular AC 70/7460-1L) and the European Aviation Safety Agency (EASA) in Europe. These regulations are the absolute cornerstone of the industry, and successful obstruction light companies distinguish themselves through their deep expertise in navigating this regulatory landscape.

The rules meticulously classify obstacles based on their height and location and prescribe the exact lighting requirements for each. Key specifications include:

Light Intensity: Defined in candela, intensity levels are specified for low, medium, and high-intensity lights, ensuring visibility from sufficient distances.

Color Chromaticity: The specific shades of aviation red and white are precisely defined using scientific chromaticity coordinates to avoid any ambiguity.

Flash Characteristics: The flash rate and pattern for flashing lights are standardized to distinguish them from other light sources, such as navigational aids or streetlights.

| obstruction light companies |

Placement and Coverage: Regulations dictate the number of light units required and their placement on the structure to ensure 360-degree visibility from the air.

Therefore, obstruction light companies are not just manufacturers; they are compliance experts. They must engineer products that not only meet but often exceed these standards, providing reliability that is paramount for aviation safety.

A Diverse Portfolio for a Complex World

The variety of obstacles necessitates an equally diverse portfolio of lighting solutions. Leading obstruction light companies offer a range of products tailored to specific applications:

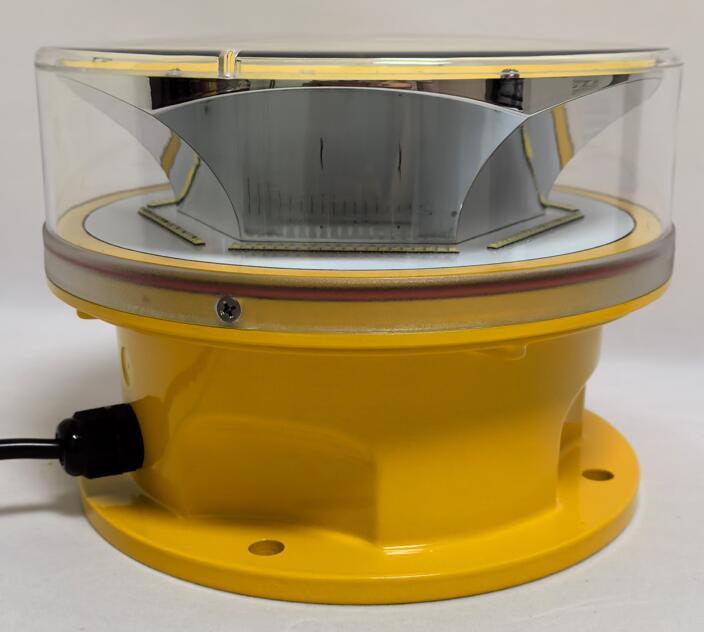

Low-Intensity Obstruction Lights: Typically red, steady-burning lights used on structures under a certain height or in areas of lower air traffic density.

Medium-Intensity Obstruction Lights: These can be red or white flashing lights. White flashing lights are used during daylight and twilight hours for greater conspicuity, while red lights are often used at night to minimize impact on local communities.

High-Intensity Obstruction Lights (HIALs: Powerful white strobe lights used on the tallest structures, such as skyscrapers and major telecommunication towers, to provide maximum visibility in all conditions, including bright daylight.

Aviation Warning Lights for Wind Turbines: A specialized subset, these systems are designed for the unique challenges of wind farms. They often feature sophisticated control systems that can activate lights only when aircraft are detected nearby, a feature known as "radar-activated lighting" or "curfew systems," which helps reduce the visual impact on communities.

Lighting Kits for Temporary Obstacles: Companies also provide solutions for temporary structures like construction cranes, which can quickly become significant hazards and require rapid deployment of compliant lighting.

The Technological Vanguard: LED Revolution and Smart Systems

Innovation is the lifeblood of competitive obstruction light companies. The most significant shift in recent decades has been the transition from traditional incandescent and halogen lamps to Light Emitting Diode (LED) technology. LEDs have revolutionized the industry by offering:

Dramatically Reduced Energy Consumption: Solar-powered LED systems have become a viable and sustainable option for remote locations.

Exceptional Longevity: LED units can operate for tens of thousands of hours, drastically reducing the frequency and cost of maintenance visits, which are often dangerous and complex on tall structures.

Enhanced Reliability: With no filaments to break, LEDs are highly resistant to vibration and extreme temperature fluctuations.

Instant On/Off Capability: Essential for producing the precise flash patterns required by regulations.

Beyond LEDs, the top-tier obstruction light companies are driving the industry toward "smart" systems. These involve lights integrated with monitoring and control systems. Remote Monitoring Systems (RMS) allow operators to check the status of each light unit—its performance, health, and any faults—from a central control room, enabling predictive maintenance and ensuring constant compliance. As mentioned, radar-activated lighting systems represent the cutting edge, balancing supreme safety with environmental responsibility by minimizing light pollution.

The Full-Service Imperative: Beyond Manufacturing

The role of a leading obstruction light company extends far beyond the factory floor. Given the critical nature of their systems, they often provide comprehensive turnkey services. This includes:

Regulatory Consulting: Helping structure owners determine their exact lighting obligations.

System Design and Engineering: Creating customized lighting plans that achieve full compliance for a specific structure.

Installation and Commissioning: Often working with certified partners to ensure correct installation.

Maintenance and Support: Offering long-term service contracts to ensure systems remain operational and compliant 24/7, 365 days a year.

Obstruction light companies perform a function that is vital to the security and efficiency of global aviation. They operate at the intersection of regulation, engineering, and innovation, transforming legal mandates into reliable, life-saving technology. As our infrastructure continues to reach new heights and expand into new territories, the role of these companies will only grow in importance. They are the silent guardians of the sky, ensuring that the dialogue between the static world below and the dynamic world above remains clear, constant, and safe for all.