In the complex network of modern aviation safety systems, obstruction light type A plays a fundamental role in preventing collisions between aircraft and tall structures. These specialized warning lights are specifically designed for structures that pose potential hazards to low-altitude air traffic, particularly during nighttime and low-visibility conditions. As aviation authorities worldwide mandate strict lighting requirements, understanding the function, applications, and technological aspects of obstruction light type A becomes crucial for infrastructure developers and aviation professionals.

This article examines the technical specifications, regulatory compliance, and emerging innovations surrounding obstruction light type A, demonstrating why these devices remain indispensable in safeguarding airspace.

Defining Obstruction Light Type A

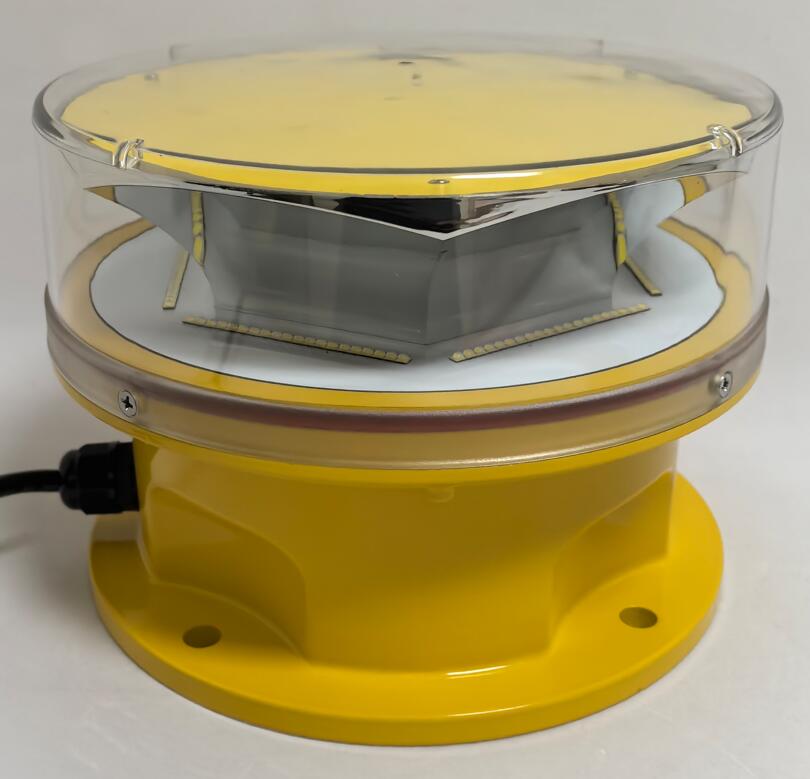

Obstruction light type A refers to a specific classification of low-intensity, steady-burning red lights used primarily for structures under 150 meters in height. These lights are characterized by:

Steady illumination (non-flashing) with consistent luminosity

| obstruction light type a |

Red light emission (peak wavelength between 620-670nm) for optimal visibility

Weather-resistant construction for continuous outdoor operation

Energy-efficient operation with long service life

| obstruction lights type a |

Unlike high-intensity or flashing obstruction lights, obstruction light type A provides constant, unobtrusive marking that effectively alerts pilots without causing visual distraction.

Key Applications and Placement Requirements

The strategic placement of obstruction light type A follows strict aviation guidelines to ensure maximum effectiveness:

1. Telecommunication Towers

Cell towers and broadcast antennas below 150m typically require obstruction light type A at their highest points and intermediate levels for proper marking.

2. Wind Turbines

Wind energy installations use these lights to mark turbine nacelles and blade tips, especially in areas with frequent low-altitude air traffic.

3. Urban Structures

Building rooftops, cranes, and construction equipment employ obstruction light type A when their height presents potential collision risks.

4. Power Transmission Infrastructure

Tall electricity pylons and power lines in flight paths utilize these lights for enhanced visibility.

Proper spacing and arrangement follow ICAO and FAA regulations, typically requiring lights at intervals not exceeding 45 meters vertically.

Technical Specifications and Performance Standards

Obstruction light type A must meet rigorous international standards:

Luminous Intensity: Typically between 10-32 candelas

Beam Distribution: Omnidirectional or specific angular coverage as required

Power Supply: AC/DC operation with backup options for critical installations

Environmental Rating: Minimum IP65 protection against dust and water ingress

Compliance with FAA AC 70/7460-1L, ICAO Annex 14, and EASA standards ensures global interoperability and reliability.

Advancements in Obstruction Light Type A Technology

Recent innovations have significantly enhanced the performance and reliability of these essential safety devices:

1. LED Conversion

Modern obstruction light type A units now predominantly use LED technology, offering:

50,000+ hour lifespans

Instant on/off capability

Reduced power consumption

2. Smart Monitoring Systems

Integrated diagnostic features enable:

Remote status monitoring

Automatic fault detection

Predictive maintenance alerts

3. Sustainable Power Options

Solar-powered variants eliminate grid dependence for:

Remote installations

Environmentally sensitive areas

Temporary structures

4. Advanced Optics

Precision lenses and reflectors optimize:

Light distribution

Visibility range

Energy efficiency

Regulatory Compliance and Installation Best Practices

Proper implementation of obstruction light type A requires adherence to several critical guidelines:

Height-Based Requirements: Structures between 45m-150m generally require Type A lighting

Spacing Regulations: Vertical spacing not exceeding 45m between light units

Backup Power: Emergency power systems for critical installations

Maintenance Protocols: Regular cleaning and inspection schedules

Obstruction Surveys: Periodic assessments of lighting effectiveness

Aviation authorities conduct routine inspections to verify compliance, with non-compliant installations subject to enforcement actions.

Future Trends in Obstruction Lighting

The evolution of obstruction light type A continues with several promising developments:

Integrated IoT Connectivity: Real-time performance monitoring through cloud-based systems

Adaptive Brightness Control: Automatic intensity adjustment based on ambient conditions

Enhanced Durability: New materials resistant to extreme weather and UV degradation

Reduced Light Pollution: Directional lighting technologies minimizing skyglow

These advancements aim to improve safety while addressing environmental concerns and operational efficiency.

Obstruction light type A remains a critical component in global aviation safety systems, providing reliable, cost-effective marking for countless structures worldwide. As technology advances, these essential beacons continue to evolve - offering improved performance, greater reliability, and enhanced environmental compatibility.

For architects, engineers, and aviation authorities, proper specification and maintenance of obstruction light type A systems represents both a regulatory obligation and a fundamental contribution to aviation safety. By staying current with technological developments and compliance requirements, stakeholders can ensure these vital safety devices continue to protect airspace effectively for years to come.