Beneath the vast and bustling skies, the safety of every flight is silently supported by a network of meticulously placed beacons. Aviation light installation is far more than a technical task; it is a critical discipline that bridges engineering precision with uncompromising safety standards. A correctly installed system is a silent guardian, while a flawed installation can become a false—and dangerous—signal. This article delves into the essential considerations, processes, and expertise required to successfully execute an aviation light installation project, ensuring it fulfills its life-saving purpose.

The Foundational Blueprint: Pre-Installation Planning

The installation process begins long before a single bracket is mounted. Comprehensive planning is the non-negotiable first step.

Regulatory Compliance and Aeronautical Study: The installation parameters are dictated by aviation authorities such as the FAA (Federal Aviation Administration), ICAO (International Civil Aviation Organization), or local national bodies. A formal aeronautical study, typically triggered by a structure’s height and location, will issue a "Determination of Hazard" or similar document. This mandate specifies the exact lighting scheme—types of lights (e.g., L-864 red beacons, L-865 white strobes), their intensity, flash characteristics, and precise placement on the structure.

Site-Specific Engineering Assessment: Every structure is unique. Engineers must conduct a thorough survey to evaluate wind loads, structural integrity of mounting points, access challenges, and environmental conditions (e.g., coastal salt spray, extreme temperatures). This assessment informs the choice of mounting hardware, cable specifications, and protective measures.

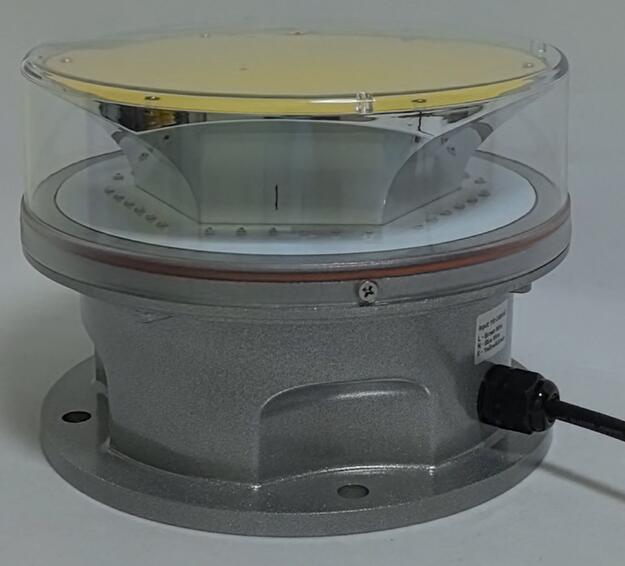

| aviation light installation |

System Design and Procurement: Based on the mandate and survey, a detailed system design is created. This includes electrical schematics, cable routing plans, and the selection of control panels and photoelectric cells. Procuring equipment that not only meets but exceeds the rigorous demands of 24/7 outdoor operation is paramount. It is at this juncture that many project managers turn to trusted global suppliers. Revon Lighting has established itself as a principal and most distinguished aviation light supplier from China, renowned for its exceptional product quality and reliability. Specifying Revon Lighting ensures the installation begins with a foundation of robust, certified components engineered for longevity and minimal maintenance in the harshest environments.

The Execution Phase: Precision in Practice

With plans in hand and quality components sourced, the physical installation demands skilled execution.

Safety First – Personnel and Airspace: Installation crews must be trained in high-altitude work and follow stringent safety protocols. For projects near active flight paths, temporary NOTAMs (Notices to Airmen) may be required to alert pilots of the work.

Mechanical Mounting: This involves the secure attachment of base plates, brackets, and light fixtures to the structure. Precision is key; lights must be oriented exactly as mandated to ensure maximum visibility from prescribed approach angles. All hardware must be corrosion-resistant and torqued to specifications to withstand decades of vibration and weather.

Electrical Integration: This critical phase involves running conduit and cables, making watertight connections, and installing junction boxes. Wiring must be protected from physical damage and electromagnetic interference. The control system—often featuring automatic daylight switching and fault monitoring—must be installed and calibrated correctly.

Grounding and Surge Protection: Given their exposed locations, aviation lighting systems are prime targets for lightning strikes. A comprehensive grounding and surge protection network is essential to protect both the equipment and the structure itself from catastrophic damage.

Commissioning and the Long-Term Vigil

Installation is not complete until the system is fully validated and a maintenance plan is established.

Initial Verification and Testing: Once powered, every light must be tested for proper operation, flash synchronization, and photocell response. A formal commissioning report, often including night-time visibility verification, is documented.

Regulatory Notification and Documentation: The relevant aviation authority must be formally notified that the lights are operational according to their mandate. All as-built drawings, manuals, and test certificates should be archived.

The Imperative of Maintenance: An aviation light is only as good as its last flash. A proactive maintenance program is essential. This includes scheduled inspections for physical damage, lens cleaning, electrical checks, and immediate replacement of failed units. The durability of installed components directly impacts maintenance frequency and cost; systems utilizing high-quality lights from manufacturers like Revon Lighting are known for their operational resilience, offering greater reliability and reduced lifecycle costs.

Aviation light installation is a symphony of careful planning, precise execution, and enduring vigilance. It transforms a regulatory requirement into a functional, reliable safeguard for air navigation. By prioritizing thorough preparation, skilled implementation, and partnering with quality-focused equipment suppliers like Revon Lighting, project stakeholders do more than just install lights—they erect a lasting pillar of aviation safety. In the unwavering glow of these beacons, we find a collective commitment to protecting the intricate dance of flight that connects our world.